Introduction

1. Ceramics are solids that have inorganic non-metallic materials as essential components. They are mainly refractory poly crystalline compounds usually inorganic like silicates, metallic oxides, carbides, hydrides, sulphides and selenides. Ceramics have been used in pottery for a very long time. Ceramics are brittle and have low tensile and impact strength. Due to these weak properties, ceramics could not find many applications. However ceramics have high compressive strength, aesthetically pleasing appearance and relative inertness to body fluids which have made ceramics extremely suitable as biocompatible materials to replace various parts of the body particularly bone, heart valve and dental crowns. Ceramics have high specific strength as fibers and they are increasingly used as reinforcing components for composite biomaterial for tensile loading applications such as artificial ligament and tendons. Ceramics have high resistance to plastic deformation and they are nonductile with zero creep. Hence ceramics are very prone to fracture at microcracks where stress concentration takes place. It is very difficult to find accurate tensile strength of ceramic which varies with the presence of microcracks. Due to this, ceramics have low tensile strength in comparison with compressive strength. A flawless ceramic is very strong even in tension. For example, flawless glass fibres are twice stronger than steel in tension. Ceramics are very hard. Alumina (Al2 O2 ) and quartz (SiO2 ) are ceramics having hardness which is little less than diamond. Ceramics are insulators having low conductivity of electricity and heat. Ceramics are refractoric materials having very high melting points. Bio ceramics can be classified as: (a) Relatively inert (nonabsorbable) (b) Semi inert (bio active) (c) Non-inert (biodegradable)

Relatively Inert (Nonabsorbable) Bio ceramics

1. As the name suggests, these bio ceramics maintain their physical and mechanical properties by resisting corrosion and wear in the hostile environment in the body tissues. They are (1) bio functional for lifetime (2) biocompatible (3) nontoxic (4) non-carcinogenic (5) nonallergic (6) non-inflammatory. They are generally used for structural support implants such as femoral heads, bone plates and screws etc. They are also used for non-structural applications as ventilation tubes, sterilization devices and drug delivery devices. Certain such bio ceramics are described in succeeding paras.

2. Alumina (Al2 O3 ): It is obtained from bauxite and corundum. Natural alumina is known as sapphire and ruby depending upon colour due to impurities present. The strength of alumina depends upon grain size and porosity. The strength is high for low grain size and low porosity. Alumina is used as biomaterial for orthopaedics and dental surgery. As it is hard it is used for watch movements and making emery paper / belt. The properties like low friction and wear, and inertness to the in vivo hostile environment have made alumina an ideal biomaterial for joint replacement. The most popular application of alumina is in total hip prostheses. It has been found that alumina hip prostheses with an UHMWPE (ultra-high molecular weight polyethylene) socket is more perfect device than metal prostheses with UHMWPE socket.

3. Zirconia (ZrO2 ): It is obtained from Zircon (Zr SiO4 ). It has high melting point and chemical stability. It can be used as implant for bone but its properties in these respect are inferior to alumina. It has good compatibility with body tissues and it is also non-active to body environment.

4. Carbons : Carbon has many allotropic forms like crystalline diamond and graphite, nanocrystalline glassy carbon and quasicrystal line pyrolytic carbon. Pyrolytic carbon is generally used for surface coating of implants. The strength of pyrolytic carbon is quite high as compared to graphite and glassy carbon as it has fewer number of flaws and unassociated carbons in the aggregate. Carbon shows excellent compatibility with tissues and blood. Pyrolite carbon coated devices are extensively used for repairing diseased heart valves and blood vessels due to high compatibility. Carbon fibers and textiles are used as reinforcement for composite biomaterials.

Semi Inert (Bioactive) Bio ceramics

1. Bioactive ceramics form strong bonds with surrounding tissues of the body on implantation. Surface reactive bio ceramics are (1) bio glasses and ceravital (2) dense and non-porous glasses and (3) hydroxyapatite. The surface reactive bio ceramics are used for (1) coating of metal prostheses to increase the bonding of implant with adjacent tissues (2) reconstruction of dental defects (3) as filler to fill the space created by donor bone, bone screw, excised tumours and deceased bone (4) as bone plate and screw (5) prostheses of middle ear ossicles (6) replacing or correcting teeth

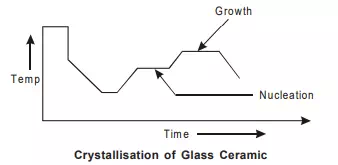

2. Glass ceramics : They are polycrystalline ceramics. In fine grained structure, they have excellent mechanical and thermal properties. Glass ceramics can be bio glass and cervital glass ceramics depending upon composition. The formation of these ceramics depends upon the nucleation and growth of small crystals and their distribution. 1010 to 10 15 nucleus per cm3 are required to develop a crystal. Certain metallic agents and ceramics are used for nucleation and crystallisation. The nucleation of glass is carried out at temperatures much lower than the melting temperature. The growth takes place at higher temperatures. The composition of cervital is similar to that of bioglass in SiO2 (40 to 50%) and CaO (20 to 30%) but differs in contents of other components (Na2 O, P2 O5 , MgO & K2 O). Glass ceramics have a very low coefficient of expansion (it can be negative also) and high resistance to surface damage due to controlled grain. Their resistance to scratching is as high as that of sapphire. The glass ceramic has brittleness which gives it a lower mechanical strength. Therefore the glass ceramics cannot be used for implant subjected to high loads like joint implants. However they are being used as filler for bone cement, dental restorative composites and surface coating material of implants.

Non-Inert (Biodegradable) Ceramics

1. Biodegradable ceramics as name suggests, degrade on implantation in the body. The absorbed ceramic is replaced by endogenous tissues. These ceramics must have controlled in vivo degradation and their degraded products should be easily absorbed by the body without any toxic effects. The rate of degradations varies from ceramic to ceramic. All biodegradable ceramics are variations of calcium phosphate except plaster of Paris and bio coral. The most common biodegradable ceramics are – (1) aluminium calcium phosphate (2) plaster of Paris (3) coralline (4) hydroxyapatite (5) tricalcium phosphate.

2. Calcium phosphate : It is commonly used in the form of artificial bone, manufacturing various forms of implants and as porous coatings on various implants. The mechanical properties of calcium phosphate vary considerably due to variations in structure and manufacturing processes. Infact our natural bones and teeth are made of a crystalline form of calcium phosphate similar to hydroxyapatite. Hence hydroxyapatite has excellent biocompatibility.

3. ALCAP ceramics : Aluminium calcium phosphate (ALCAP) ceramics have unique characteristic that they have a multi-crystallographic structure and the phase of the ceramic can be rapidly resorbed on implantation. ALCAP is prepared from AlO2 Ca O2 and P2 O5 . ALCAP has insulating dielectric properties but it has no piezoelectric or magnetic properties.

4. Corals: They have structural similarity to bone and therefore they are used for bone implants. They provide excellent structure for the ingrowth of bone as their main component calcium carbonate is gradually resorted by the tissues. Modified corals resemble cancellous bone.

5. Tricalcium phosphate (TCP) ceramics: They are used for correction of periodontal defects and augmentation of bony contours. The ceramic can be grounded and sieved to obtain desired size particles for use as bone substitutes and also for making ceramic matrix for drug delivery systems. TCP sets and hardens on addition of water.