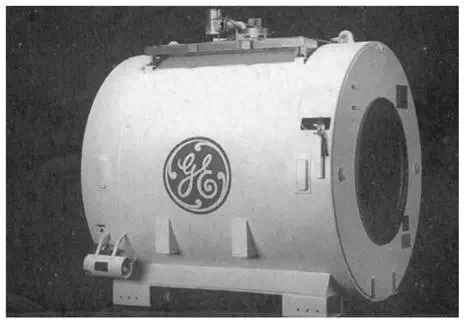

Since the early 1980s, the use of cryogenically cooled superconducting magnets [Wilson, 1983] has been the most satisfactory solution to the problem of producing the static magnet field for MRI scanners. The property of exhibiting absolutely no electrical resistance near absolute zero has been known as an exotic property of some materials since 1911. Unfortunately, the most common of these materials, such as lead, tin, and mercury, exhibit a phase change back to the normal state at relatively low magnetic field strengths and cannot be used to produce powerful magnetic fields. In the 1950s, a new class of materials (type II superconductors) was discovered. These materials retain the ability to carry loss-free electric currents in very high fields. One such material, an alloy of niobium and titanium, has been used in most of the thousands of superconducting whole-body magnets that have been constructed for use in MRI scanners (Figure 12.8). The widely publicized discovery in 1986 of another class of materials which remain superconducting at much higher temperatures than any previously known material has not yet lead to any material capable of carrying sufficient current to be useful in MRI scanners.

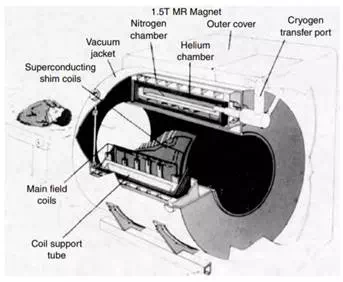

Figure 12.9 illustrates the construction of a typical superconducting whole-body magnet. In this case, six coils of superconducting wire are connected in a series and carry an intense current — on the order of 200 A — to produce the 1.5-T magnetic field at the magnet’s center. The diameter of the coils is about 1.3 m, and the total length of wire is about 65 km (40 miles). The entire length of this wire must be without any flaws — such as imperfect welds — that would interrupt the superconducting properties. If the magnet wire has no such flaws, the magnet can be operated in the persistent mode — that is, once the current is established, the terminals may be connected together, and a constant persistent current flow indefinitely so long as the temperature of the coils is maintained below the superconducting transition temperature. This temperature is about 10 K for niobium–titanium wire. The coils are kept at this low temperature by encasing them in a double-walled cryostat (analogous to a Thermos bottle) that permits them to be immersed in liquid helium at a temperature of 4.2 K. The gradual boiling of liquid helium caused by inevitable heat leaks into the cryostat requires that the helium be replaced on a regular schedule. Many magnets now make use of cryogenic refrigerators that reduce or eliminate the need for refilling the liquid helium reservoir. The temporal stability of superconducting magnets operating in the persistent mode is truly remarkable — magnets have operated for years completely disconnected from power supplies and maintained their magnetic field constant to within a few parts per million. Because of their ability to achieve very strong and stable magnetic field strengths without undue power consumption, superconducting magnets have become the most widely used source of the main magnetic fields for MRI scanners.

FIGURE 12.8 Superconducting magnet. This figure shows a 1.5-T whole-body superconducting magnet. The nominal warm bore diameter is 1 m. The patient to be imaged, as well as the RF and gradient coils, are located within this bore. (Courtesy of General Electric Medical Systems. Reprinted with permission from Schenck and Leue, 1991.)

FIGURE 12.9 Schematic drawing of a superconducting magnet. The main magnet coils and the superconducting shim coils are maintained at liquid helium temperature. A computer-controlled table is used to advance the patient into the region of imaging. (Reprinted with permission from Schenck and Leue, 1991.)